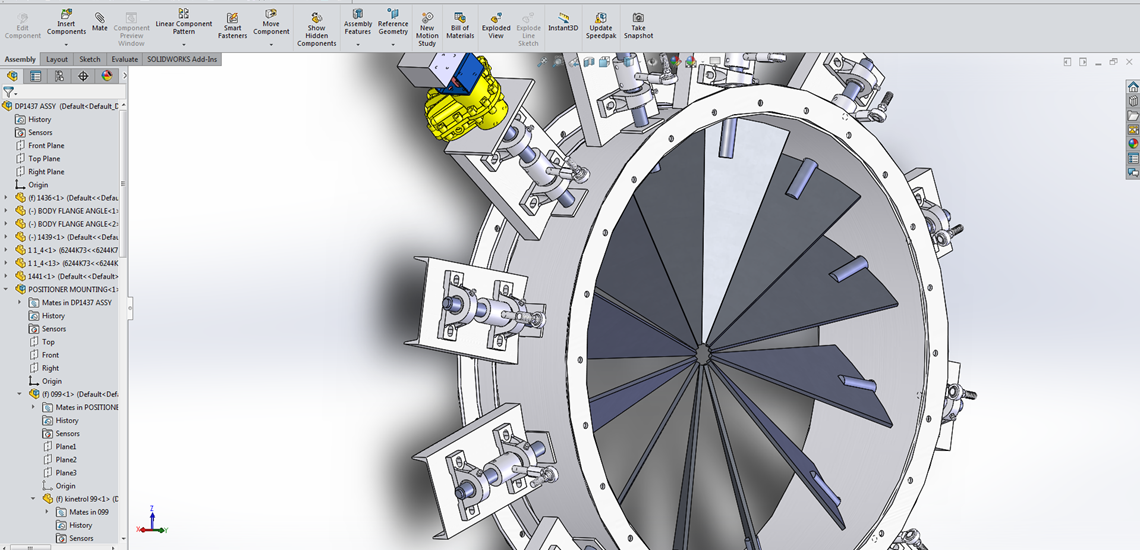

SolidWorks 3D CAD Computer Design

TRIVACO utilizes SolidWorks 3D CAD software to design and test our products. SolidWorks software provides a complete selection of best-in-class tools and features that help us get products to customers faster. Using a three dimensional software system to design our products allows us too completely and accurately model every aspect of every part that is required to complete our design. SolidWorks software uses a parametric design core which allows universal change to modified and revised parts after original design. This proves to be most useful since well over 90% of our designs are custom built to specific customer specifications. TRIVACO realized the power of computer aided design through the use of AutoCAD years ago. Although we still use AutoCAD for our two dimensional designs, our customers needs have changed to include highly specialized components that require complex specifications and clearances of an entire assembly not just individual parts. SolidWorks allows us to combine the specialized components into a complete three dimensional assembly to reach the specific goal of the customer. Clearance issues are a thing of the past since any obstruction in the field can be added into the three dimensional world of a TRIVACO designed SolidWorks assembly.

Design And Engineering Process

TRIVACO starts a new design by first compiling a list of the customer’s specific needs and wants to prioritize the most important aspects and goals of our customer. Once the list has been arranged the design process starts. Most important criteria are incorporated into the design first. For example, if we were building a louver damper for a customer one of the most important things that customer wants is for the newly designed damper to be able to bolt right in to the existing duct work instead of having to rework everything to fit the new damper. The customer already has to replace the damper, they don’t want to spend extra time and money on reworking duct work unless necessary. With this in mind, the flanges would be the first thing designed to ensure a direct “bolt in” fit. When all of the components are modeled the individual parts are then arranged to exact specifications to build a completed, full scale 3 dimensional assembly of the finished design. The competed design assembly may then be analyzed for structurally integrity and sent to the customer via e-mail or the World Wide Web for approval. All this is accomplished thru the use of a free SolidWorks viewer called “E-Drawings”. The customer has the ability to redline markup the individual parts or the completed assembly to match their specifications all via electronic data which provides instant access to our design. After approval and customers revisions are made SolidWorks provides automatic drawing creation based on and directly related to the components previously designed. This means that since the part was modeled using all three dimensions a two dimensional drawing is easily created with all tolerances and notes made on the original model. Once the new engineering designs are passed to our Fabrication and Machining department, the parts creation and assembly begins. TRIVACO can make any part for any situation.